What is 3D bioprinting and how does it work?

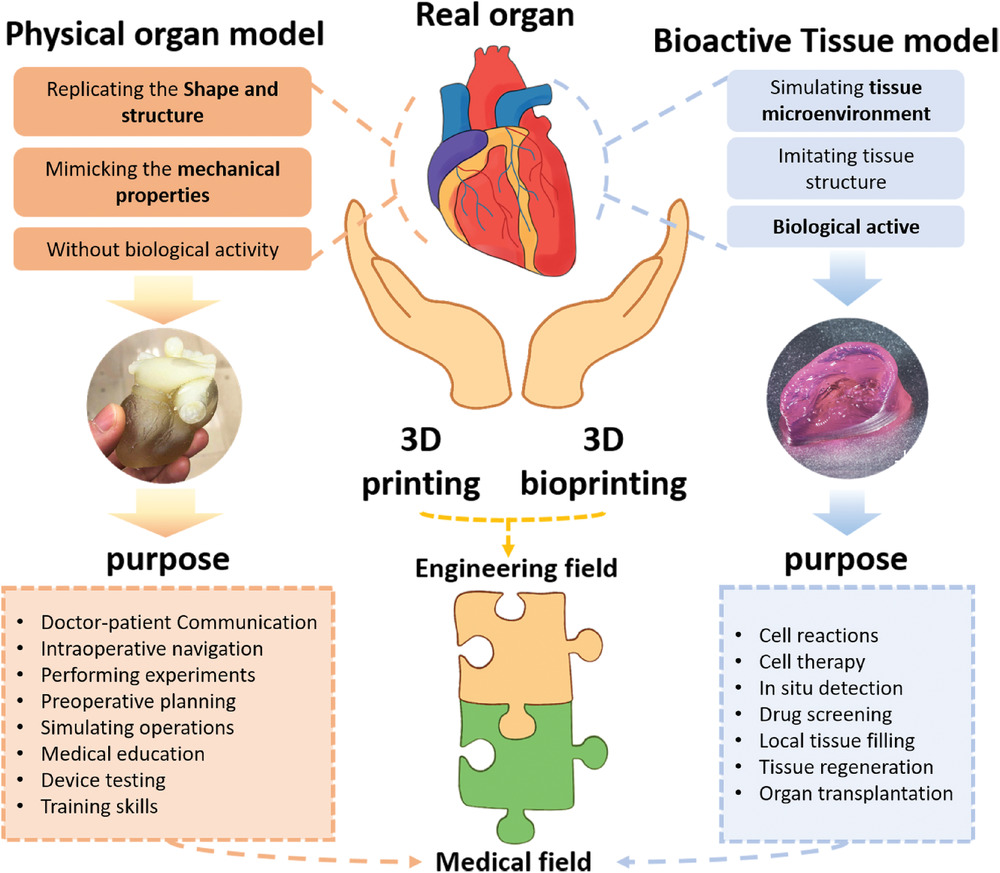

3D bioprinting or bioprinting is an additive manufacturing process that uses organic and biological materials such as living cells and nutrients as bioinks to combine and create artificial structures that imitate natural human tissues. Charles Hull was the first one in 1984 to patent his commercial 3D printing technology followed by Robert J. Klebe’s inkjet printer for printing cells in 1988.

After these first steps, the field has constantly evolved with new methods and techniques being discovered for countless possibilities and opportunities making bioprinting a popular technology. The bioprinted structures enable researchers to study the functions of the human body in vitro as they are more biologically relevant compared to in vitro studies performed in 2D (1,2).

How does 3D bioprinting work

The 3D bioprinting process follows roughly these basic series of steps:

Preparation: To get as much information as possible about biological structures, computed tomography and magnetic resonance imaging scans are used followed by 3D modeling of the structures generated by special software. The bioink type to be used for the process depends on the printing method of the particular bioprinter. For example, in the extrusion-based bioprinting method, the bioink should be a highly viscous fluid to help maintain the architecture of the model.

Construction: The printing or bioprinting process involves additive deposition of the material layer-by-layer imitating the structure of natural tissues.

Post-bioprinting: once printed, it is important to properly solidify and cross-link the material to maintain the mechanical and chemical properties of the printed structure. It can be achieved by UV light treatment, temperature control, or chemical methods. Finally, upon crosslinking, the model is incubated to create a favorable environment for cell proliferation and tissue growth (3,4).

| Advantages of 3D bioprinting | Disadvantages of 3D bioprinting |

| Mimics the real bio-structures | Ethical concerns over applications |

| Possible to explore patient-specific solutions | Quite expensive technology |

| Decreases burden on animal testing | High energy usage |

| Consistent structures, less human errors | Difficulty in maintaining cell environment |

References

1. Dey M, Ozbolat IT. 3D bioprinting of cells, tissues and organs. Sci Rep. 2020 Aug 18;10(1):14023. doi: 10.1038/s41598-020-70086-y. PMID: 32811864; PMCID: PMC7434768.

2. Gu Z, Fu J, Lin H, He Y. Development of 3D bioprinting: From printing methods to biomedical applications. Asian J Pharm Sci. 2020 Sep;15(5):529-557. doi: 10.1016/j.ajps.2019.11.003. Epub 2019 Dec 17. PMID: 33193859; PMCID: PMC7610207.

3. Papaioannou TG, Manolesou D, Dimakakos E, Tsoucalas G, Vavuranakis M, Tousoulis D. 3D Bioprinting Methods and Techniques: Applications on Artificial Blood Vessel Fabrication. Acta Cardiol Sin. 2019 May;35(3):284-289. doi: 10.6515/ACS.201905_35(3).20181115A. PMID: 31249458; PMCID: PMC6533576.

4. Gungor-Ozkerim PS , Inci I , Zhang YS , Khademhosseini A , Dokmeci MR . Bioinks for 3D bioprinting: an overview. Biomater Sci. 2018 May 1;6(5):915-946. doi: 10.1039/c7bm00765e. PMID: 29492503; PMCID: PMC6439477.

5. https://sites.google.com/site/gsse2014b2/pros-cons