SCALE UP CULTURES AT INDUSTRIAL OR LARGE SCALE LEVELS

As the new technologies are evolving along with the new discoveries, there is a huge need to scale up and speed up the process of producing cells at a larger scale. Below are the commonly preferred devices used to scale up the cultures at industrial scale.

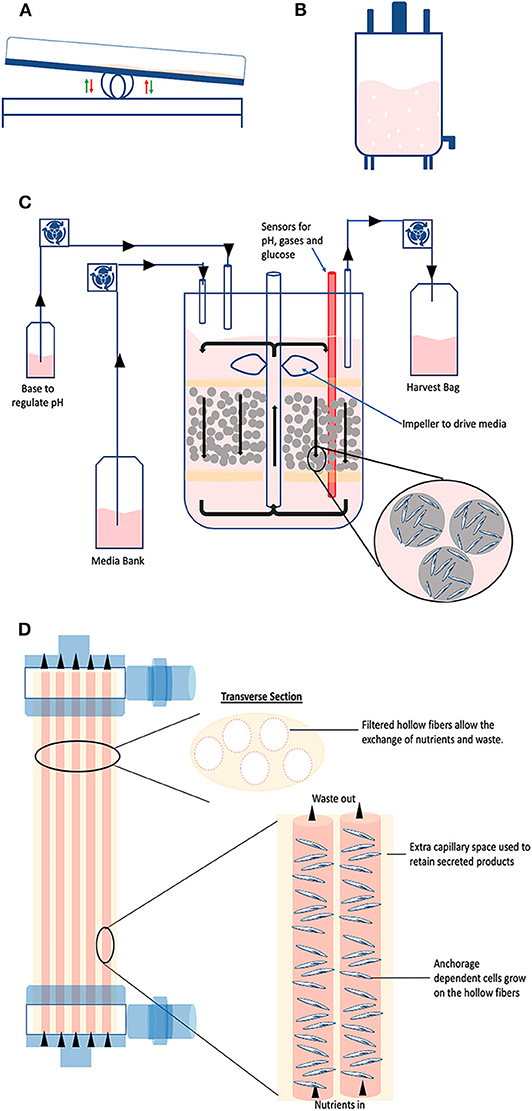

ROCKING MOTION BIOREACTORS : this type of reactors utilizes the wave motion of the culture medium by rocking the platform to provide a cell beads suspension. The beads can be placed inside a bag with ports that allows air circulation. The agitation provides proper mixing and mass transferred while the circulating air provides the necessary oxygen exchange. They can hold up to 500 L of the volumes. Such systems are widely used for expansion of mammalian cells, T cells or neutrophils. These reactors also allow high cell yields, which are a perfect suited platform of choice when expanding high density cell banks (1).

STIRRED TANK BIOREACTORS: they are possibly the most used system for large scaled culture of mammalian cell cultures. They apply the same principle as spinner flasks, agitation in a tank via magnetic beads. These beads keep the solution in agitation to maintain the organoids, suspension, or the micro-carrier in the suspensions along with homogenization of oxygen distribution, heat and nutrition. Industrial stirred tank bioreactors are variable as single-use, however they are made of stainless-steel materials, considering it to be clean, well-compatible with biological materials and resistant to high pressures and erosion. The tank provides a closed and automated platform and can be operated in different models such as batch fed, batch, and perfusion (1,2).

PACKED BED BIOREACTORS: they consist of a hollow tube packed at the bottom with immobilized surface such as scaffolds, micro-carriers, or porous fibers. The cells are seeded on the fixed bed while the fresh medium is continuously supplied. Circulated within the system transferring oxygen and nutrients along with the larger surface are: volume ratios. This also impacts the cell passages as with the high surface area the cells can be passaged less often, thereby reducing the cost of culture medium. They can up-scale up to 500 m2. However, the cell harvesting can become challenging due to the presence of high cell densities and the difficulty of effectively introducing the detachment supplement into the culture (3,4).

HOLLOW FIBER BIOREACTORS

they consist of a cylindrical chamber stacked with a semi-permeable hollow fiber. cells can be inoculated within the fibers and on the extra-capillary surfaces which permits high cell densities. The culture medium can flow through the fibers or chambers or both using the proper channels and ports, and depending on the inoculation methods, pore size for semi-permeable membrane can be determined while particles shall pass through or retained by the membrane. Due to its perfusion rates, it allows automated monitoring and control of metabolites concentration which is of most importance in maintaining the process in continuity. To increase cell production, it is also possible to connect various units in parallel (5,6).

REFERENCES

- Singh V. Disposable bioreactor for cell culture using wave-induced agitation. Cytotechnology. (1999) 30:149–58. doi: 10.1023/A:1008025016272

- Nienow AW, Rafiq QA, Coopman K, Hewitt CJ. A potentially scalable method for the harvesting of hMSCs from microcarriers. Biochem Eng J. (2014) 85:79–88. doi: 10.1016/j.bej.2014.02.005

- Rafiq QA, Heathman TR, Coopman K, Nienow AW, Hewitt CJ. Scalable manufacture for cell therapy needs. In: Bioreactors. Wiley-VCH Verlag GmbH & Co KGaA (2016). p. 113–146. doi: 10.1002/9783527683369.ch4

- Kumar A, Starly B. Large scale industrialized cell expansion: producing the critical raw material for biofabrication processes. Biofabrication. (2015) 7:044103. doi: 10.1088/1758-5090/7/4/044103

- Godara P, McFarland CD, Nordon RE. Design of bioreactors for mesenchymal stem cell tissue engineering. J Chem Technol Biotechnol. (2008) 83:408–20. doi: 10.1002/jctb.1918

- Housler GJ, Miki T, Schmelzer E, Pekor C, Zhang X, Kang L, et al. Compartmental hollow fiber capillary membrane–based bioreactor technology for in vitro studies on red blood cell lineage direction of hematopoietic stem cells. Tissue Eng C Methods. (2012) 18:133–42. doi: 10.1089/ten.tec.2011.0305