SMALL SCALING UP TECHNOLOGIES FOR CELL CULTURES

With the evolving tools of molecular biology and biotechnology, many scientists have found out a way to scale up the cell cultures to produce enough amounts of cells or contained medium for further purifications or subcellular fractions. Frequently used devices to scale up adherent cells at bench scale levels are:

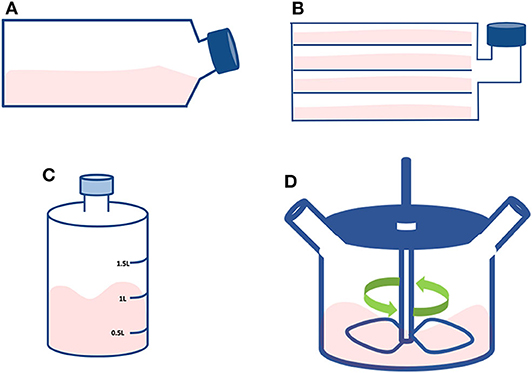

T-FLASKS : they are most commonly used plastic consumables for early-stage cell expansion, usually when growing cells which are cryopreserved. T flasks vary in size, ranging from a culture area of 12-225 cm2. They are usually composed of disposable plasma treated polystyrene or tissue culture plastic. These are economical, albeit being labor-intensive, when there is a need to expand the cells beyond the bench scale levels (1).

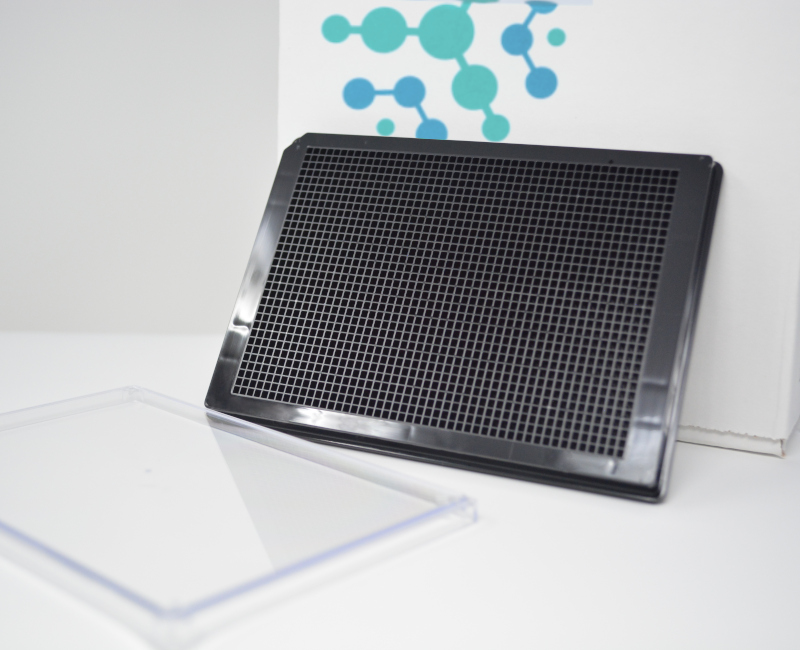

MULTI-LAYERED FLASKS : These are large T flasks composed of stacked flat surfaces. The aim here is to increase the available surface area by incorporating a multi-tray unit reaching to a total area depending upon the number of layers, generally 2.5 m2. They can be treated as an individual unit with the cells from each layer to be seeded, cultured, and detached at the same time (1).

ROLLER BOTTLES : These bottles consist of cylindrical vessels to grow cells in a dynamic system. They are usually placed in a heated environment on a rack that slowly revolves- around 5-240 revolutions/hour. The cells can attach and cover the inner surface of the roller bottle, causing the cells to bathe in the culture medium continuously while concurrently being exposed to the gasses. Additionally, rotation also provides a level of mixing which prevents gradients from forming within the medium that might affect the cell growth. The surface area available for expansion is between 500-1700 cm2 (2).

SPINNER FLASKS : These are flat bottom flasks commonly used at the bench, for suspension cultures that can be used to validate media composition and micro-carriers. The culture is maintained in suspension and the stirring is achieved by a magnetic bar. The medium along with the cells are inoculated with a total volume of 100-200 ml at stirring speed of 50 rotations per minute. Furthermore, micro-carriers can also be added to spinner flasks mainly to do primary tests before moving onto the larger scales (2,3).

REFERNECES:

- Randers-Eichhorn L, Bartlett RA, Sipior J, Frey DD, Carter GM, Lakowicz JR, et al. Fluorescence-lifetime-based sensors: oxygen sensing and other biomedical applications. In: Laser-Tissue Interaction VII. San Jose, CA: International Society for Optics and Photonics, 147–158.

- Clapp KP, Castan A, Lindskog EK. Upstream processing equipment. in Biopharmaceutical Processing. Amsterdam: Elsevier, 457–476. doi: 10.1016/B978-0-08-100623-8.00024-4

- Tsai AC, Ma T. Expansion of human mesenchymal stem cells in a microcarrier bioreactor. in Bioreactors in Stem Cell Biology. New York, NY: Springer, 77–86. doi: 10.1007/7651_2016_338